Can You Use Rammed Earth for Floors? (See These 5 Examples)

A good earthen floor should be free from dampness, easy to clean, durable, and fire resistant.

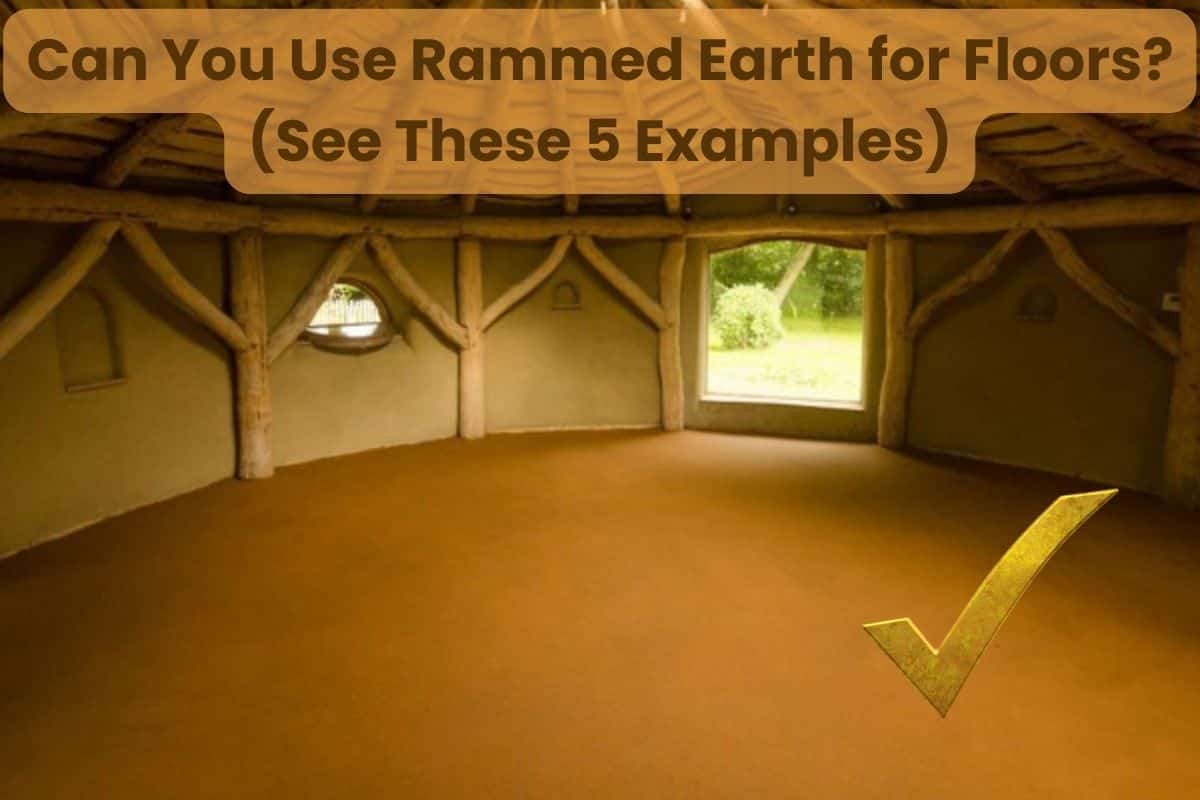

Since rammed earth is one of the many natural materials you can use in construction, you may contemplate using it for your flooring.

It can be made from local materials and contains little embodied energy, reducing your carbon footprint.

However, the possibility of rammed earth being susceptible to water may leave you wondering whether it’s a good idea to use earthen floors or not.

You can use rammed earth for floors if you install a vapor barrier and capillary break layer. Since rammed earth is susceptible to water, you must prevent soil porewater from rising into the floor by installing pea gravel and a vapor barrier made of polyethylene or similar materials.

In the rest of this article, I’ll discuss five examples of earthen floors.

I’ll also discuss how to seal earthen floors for a pleasant indoor environment.

Let’s get started!

For other sustainable flooring options, you could consider hemp wood floors, or for a bit of luxury, sustainable carpeting.

1. Tataki – Earth Floors in Japan

Tataki is a name used to refer to traditional Japanese earthen floors.

The term “Tataki” means three and earth. It describes the composition of Japanese earthen floors. The Japanese earthen floor mix materials are lime, earth, and bittern (salt).

Aggregates are also added to balance clayey soils and lime.

During its construction, a 100-150 mm layer of crushed gravel is added to the earthen floor before compacting. This prevents moisture from seeping via capillary action up into the floor, keeping it durable.

Once the gravel is set, the three layers used in this earth floor are layered, evened, compressed, and compounded on the same day to prevent the accumulation of cold joints.

2. Great Mosque of Djenné

The Great Mosque of Djenné is an excellent example of a rammed-earth architecture project.

Located in Djenné, present-day Mali, the Great Mosque of Djenné was built in 1907 using mud. The main architect, Ismaila Traoré, used traditional earthen material and palms to construct the mosque.

The mosque’s floor is composed of sandy earth mixed with aggregates and lime to harden the soil. The earth floor was plastered with mud to improve the mosque’s aesthetic appeal.

The mosque’s walls are made of sun-baked earth bricks (ferey), earth-based mortar, and sand. The entire wall is coated with plaster for a smooth finish.

The Great Mosque of Djenné is a good example of earthen architecture; its popularity attests to the appeal and longevity of earthen floors.

3. METI Handmade School

METI Handmade School in Rudrapur, Bangladesh, is one project constructed using an earth floor.

The use of traditional and local materials in designing this school aimed at reflecting the METI philosophy – learning with joy aided by the material, architectural design, and construction techniques.

The METI Handmade School has an earthen floor lined with straw to keep vapor at bay.

Although the foundation is made from earth, it is reinforced with bamboo, and the walls are made of traditional mud bricks.

The earth floor used in this school proved successful, offering strong stability that can hold up to Bangladesh’s heavy monsoons.

4. Auroville Visitors Centre

The Auroville Visitors Centre in India is an example of successful rammed-earth architecture in the modern world.

The entire project was made from stabilized earth blocks to serve, in part, as a training center for local artisans in earth-related projects like brickmaking.

The earthen floor, was modified with natural stones due to its exposure to groundwater. The modification improved the floor’s stability, making it more resistant to water damage.

5. Fired Ceramic ‘Geltaftan’ Buildings

Iranian architect, Nader Khalili, is the person behind the Geltaftan buildings. These structures were made from earth materials high in clay content and fired into ceramic.

Khalili knew he could make permanent water and earth-quake-resistant structures by combining earth and water. He could then use fire and air to finish the form created from water and earth.

The finished material created excellent ceramic buildings with water-resistant floors. The earthen floors also had a high thermal mass that insulated the home from extreme temperatures, providing a comfortable indoor climate.

How Do You Seal an Earthen Floor?

Unlike a concrete floor, an earthen floor is highly susceptible to water penetration and abrasion.

Therefore, you must seal the final surface of earthen floors with an appropriate sealant to provide a hard and waterproof finish to protect them from damage and extend their lifespan.

Sealing an earthen floor with natural linseed oil or wax provides a waterproof finish and a final layer of protection without compromising its breathability. Applying multiple layers of these sealants will help make the floor more resistant to water penetration and abrasion.

Earthen floors are sealed using drying oils like linseed oil. These oils form a plastic-like washable seal when applied multiple times.

The following is the procedure to seal an earthen floor using a finish coat of linseed oil:

- Heat the oil: The first step is to heat the oil for efficient soaking and to help the floor absorb it. You don’t need to heat the oil to its boiling point. A rule of thumb is to heat it to about 240 and 260°F (115.56 and 126.67°C) in an open space.

- Transfer the heated oil into a suitable container: Pour the oil into a wide-open container for easy application.

- Apply the heated oil: Once all necessary safety precautions, like wearing gloves, are taken, apply the hot oil to the earthen floor using a thick brush or roller.

- Allow the oil to dry between coats: Allow adequate time between each coat of heated oil to ensure it dries thoroughly.

Here is a video demonstrating the above oiling process:

How Strong Is an Earthen Floor?

When appropriately sealed to prevent capillary action from drawing moisture up into the floor from the ground, earthen floors are strong and durable.

Sealing these earthen floors is an excellent way to strengthen them and extend their lifetime. With proper maintenance, you can rest assured that these floors can last longer without frequent repairs or costly maintenance.

Stabilized earthen floors are even stronger than regular earthen floors because they have more compressive strength and better thermal mass.

Organic materials like straw, reeds, bamboo, or jute fibers strengthen the structure of rammed earth floor slabs.

Final Thoughts On Rammed Earth for Floors

It’s clear that, in the right situation, earth floors can be a viable alternative to a concrete slab.

You’ll need to seal earthen floors with a finish coat of oil or wax to make them more resistant to water penetration and abrasion.

Moreover, using materials such as straw to increase their strength when installing earth floors is wise.

Adequately sealed to keep them completely dry, these floors can last longer and provide an excellent indoor climate. Adding underfloor heating pipes during construction will warm earthen floors and add a luxurious touch.

The decision ultimately lies with you on incorporating an earth or adobe floor into your project. Choose natural building methods that work best for your design needs and lifestyle.

If this article has inspired you to learn more about earthen construction techniques, you can read our article “All About Compressed Earth Blocks: Pros And Cons To Consider.”