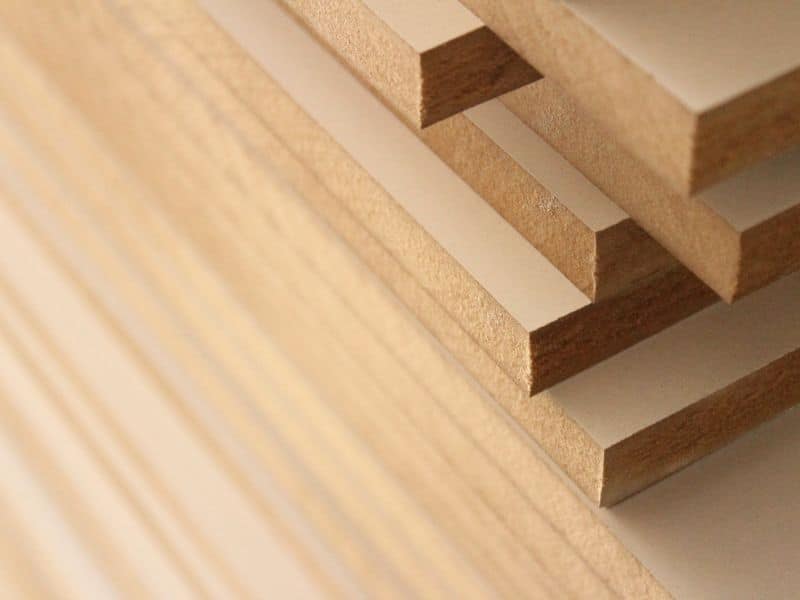

What Is Manufactured Wood? Main Types Plus Pros and Cons

If you love your furniture or buildings to be made from wood, you have only two options – solid wood and manufactured wood.

However, manufactured wood is becoming a more popular option due to the continued push for sustainable construction. But what is manufactured wood?

Manufactured wood, also known as engineered wood, is made by heating, compressing, and binding wood fibers, strands, particles, or veneers with adhesives. The resulting product resembles natural wood, is easy to work with, and is cheaper than solid wood.

In the rest of this article, I’ll discuss the types of manufactured wood, how they are made, and their pros and cons.

I’ll also discuss how these types of manufactured wood compare to make your selection process easier. Let’s dive in!

Types of Manufactured Wood

The following are the main types of manufactured wood:

Oriented Strand Board (OSB)

Oriented Strand Board (OSB) is a manufactured wood made from thin wood strands.

OSB is made by mixing waterproof resin, like pMDI or PF, with thin wood strands and interleaving them into thick mats. The mats are then subjected to high heat and pressure for bonding.

The product resulting from the above process is a solid, uniform building board with excellent strength and water resistance.

OSB is suitable for various applications, including:

- Roofing.

- Floor underlayment.

- I-joist in commercial and residential buildings.

Pros

- It’s cheaper.

- It’s lighter.

- It possesses a consistent density.

Cons

- It retains moisture.

- It’s susceptible to swelling and warping along the edges.

Particleboard

Particleboard is another type of manufactured wood made from smaller wood chips.

It’s possible to confuse particle board with OSB as the two look similar. However, the main difference lies in the materials they are made from. While OSB is made from thin wood strands, particleboard is made from smaller wood chips.

Particleboard, or chipboard, is a flat board, low-density wood that’s affordable and suitable for many different projects.

It’s made by mixing waterproof resin, like pMDI, PF, or wax, with wood chips. The mixture is interleaved into mats, hot-pressed, and then finished.

It’s suitable for:

- Flooring underlayment.

- Countertops.

- Shelving.

- Home decking.

- Stair treads.

Pros

- Budget-friendly.

- Aesthetically appealing due to its neat surface.

- Ideal for decorative laminates due to its soft surfaces.

- It’s lightweight and easy to work with.

Cons

- Unsuitable for heavy loads due to its low strength.

- It’s toxic due to the use of urea-formaldehyde resin.

- It’s susceptible to warping and bending because it absorbs moisture.

- It doesn’t hold well to nails and screws due to its brittle composition.

Medium-Density Fiberboard (MDF)

MDF is what most people think of when it comes to manufactured wood.

Unlike the rest, MDF is a strong and flexible wood suitable for various applications. It’s a preferred option by many woodworkers due to its unique strength and flawless surface.

MDF is made by dehydrating sawdust and shavings. After dehydration, these materials are glued together using resin and wax.

The combination of shavings, sawdust, resin, and wax is then subjected to heat and pressure until it bonds to a medium-density fiberboard.

MDF is mainly used for:

- Laminate flooring.

- Making door parts.

- Kitchen cabinets.

- Millwork.

- Moldings.

Pros

- It can hold heavy loads due to its high density and strength.

- Flawless painting and finishing due to its smooth surface.

- It’s highly stable; thus, it doesn’t warp or bend due to temperature fluctuations.

- It’s cost-effective.

Cons

- Highly susceptible to damage and sags if handled roughly.

- It’s difficult to work with because it’s heavy and denser.

- It’s highly susceptible to water damage.

Plywood or Laminated Board

Plywood is one of the most famous manufactured woods. It’s made by pressing and binding fine layers of thin sheets of wood.

Usually, plywood consists of three or more sheets of wood bonded together with an adhesive. The sheets are laid so that their wood grains are 90 degrees from each other.

The production process involves four steps:

- Laying the back veneer and running it through a glue spreader.

- Laying the short section of the core veneer on top of the glued back veneer and running it through a glue spreader.

- Laying the face veneer on the glued core and stacking it with other sheets.

- Hot-pressing the glued sheets at pressures between 110-200 psi and temperatures between 230-315°F (110-157.22°C).

Plywood is suitable for:

- Flooring.

- Partitioning.

- Sheathing.

- Ceilings.

Pros

- It’s strong and durable.

- High dimensional stability.

- It’s excellent at holding nails and screws.

Cons

- It is expensive.

- It’s difficult to work with due to its high strength.

- It’s hard to get a smooth cut because its edges are prone to splintering.

Veneer Wood

Veneer wood is a “paper thin” cut of wood that is typically glued onto core panels. It’s often used to help reduce the cost and weight of furniture while still giving it the look and feel of natural wood.

Veneer wood is made by peeling tree trunks or slicing through flitches. It’s suitable for:

- Cabinets.

- Panel doors.

- Wear layer of flooring.

- Furniture.

- Tabletops.

Pros

- It’s aesthetically pleasing.

- It’s lightweight and easy to work with.

- It’s cost-effective.

Cons

- It can be easily damaged due to its thinness.

- The veneer often begins to peel off over time if not sealed properly.

The table below summarizes the differences between manufactured wood and solid wood:

| Feature | Manufactured Wood | Solid Wood |

| Refinishing | Limited refinishing (up to 3 times) | It can be refinished several times |

| Thickness | Typically 1.25 inches (31.75 mm) with 5-inch (127 mm) wide planks | 2.25 inches (57.15mm) with 5-11-inch (127-279.4-mm) wide planks |

| Maintenance | High | Low |

| Durability | 25 to 30 years | More than 100 years |

| Production | Binding multiple layers of wood, sawdust, and veneers | Cutting down fully-grown trees |

| Installation | Easy | Difficult |

| Cost | Inexpensive | Expensive |

| Weight | Lightweight to heavy, depending on the type | Heavy |

Table 1: Summary of manufactured wood vs. solid wood

What Are Advantages of Manufactured Boards?

The advantages of manufactured boards include the following:

- They are highly resistant to moisture.

- They are customizable.

- They are cheap.

- They are lightweight.

- They are cost-effective.

What Are the Disadvantages of Manufactured Wood?

The disadvantages of manufactured wood include the following:

- Low durability.

- Off-gassing.

- Not recyclable.

- Some types are unsuitable for load-bearing.

Is Manufactured Wood Better Than Solid Wood?

Some types of manufactured wood are structurally weak compared to solid wood.

Although solid wood is expensive, it has a natural grain and strength that some types of manufactured wood, such as particleboard, can’t replicate.

Solid wood also offers a more aesthetically-pleasing look compared to many types of manufactured wood. Although costly, the long-term durability of solid wood makes it worth the investment.

What Are MDF Advantages and Disadvantages?

The advantages of MDF include the following:

- Cost-effective.

- It’s easy to drill and cut without damaging it.

- It’s a high-density material.

- It’s stable and durable.

- It contributes to sustainable building.

- Is easy to stain and apply color.

The disadvantages of MDF include:

- It’s structurally weak.

- Contains VOCs.

- It might be challenging to work with due to its high density.

Does Manufactured Wood Scratch Easily?

Manufactured wood scratches easily due to the top layer veneer made from hardwood. The veneer layer is thin and more likely to be seriously damaged when scratched. It’s also prone to fading and discoloration when exposed to direct sunlight for long periods.

Is Manufactured Wood Waterproof?

Most manufactured wood, such as MDF and Particleboard, is not waterproof; thus, it’s highly susceptible to water damage. The fact that engineered wood is moisture-resistant doesn’t make it waterproof. It will be damaged, just like solid wood, if exposed to standing water.

How Long Does Manufactured Hardwood Last?

Manufactured wood lasts between 25 and 30 years because it can’t be refinished to extend its durability. The lifespan depends on care and maintenance.

Regular cleaning can help prolong its service life, while improper handling and high-traffic areas can reduce its durability.

How Do You Care for Manufactured Wood?

You can care for manufactured wood by:

- Maintaining the relative humidity at 40 to 65%.

- Placing an abrasive matt at the external door to prevent scratches.

- Cleaning it regularly with a damp cloth and mild detergent.

- Using furniture wax to help protect the wood from scratches.

- Avoiding contact with direct sunlight, heat sources, or humidity extremes.

Can Manufactured Wood Be Refinished?

While some manufactured wood can’t be refinished, those that can be refinished have a limited number of times it can be done. Refinishing manufactured wood that has a thinner wear layer is not advisable, as this can expose the core layer.

However, if your manufactured wood is viable for refinishing, you can do it between 1 and 3 times. Refinishing your manufactured wood more than three times will damage its core layer.

Therefore, it’s best to opt for engineered wood flooring with thicker wear layers to extend your floor’s service life by allowing you to refinish.

What Is Manufactured Wood – Final Thoughts

There you have it – the lowdown on manufactured wood.

While it might not be as glamorous as solid wood, it has advantages. From affordability to moisture resistance, this material has a lot to like.

Of course, as with any building material, some drawbacks exist.

You can decide whether manufactured wood suits your project by weighing the pros and cons against your needs.

Besides manufactured wood, here are other sustainable building materials you can use for your next build.