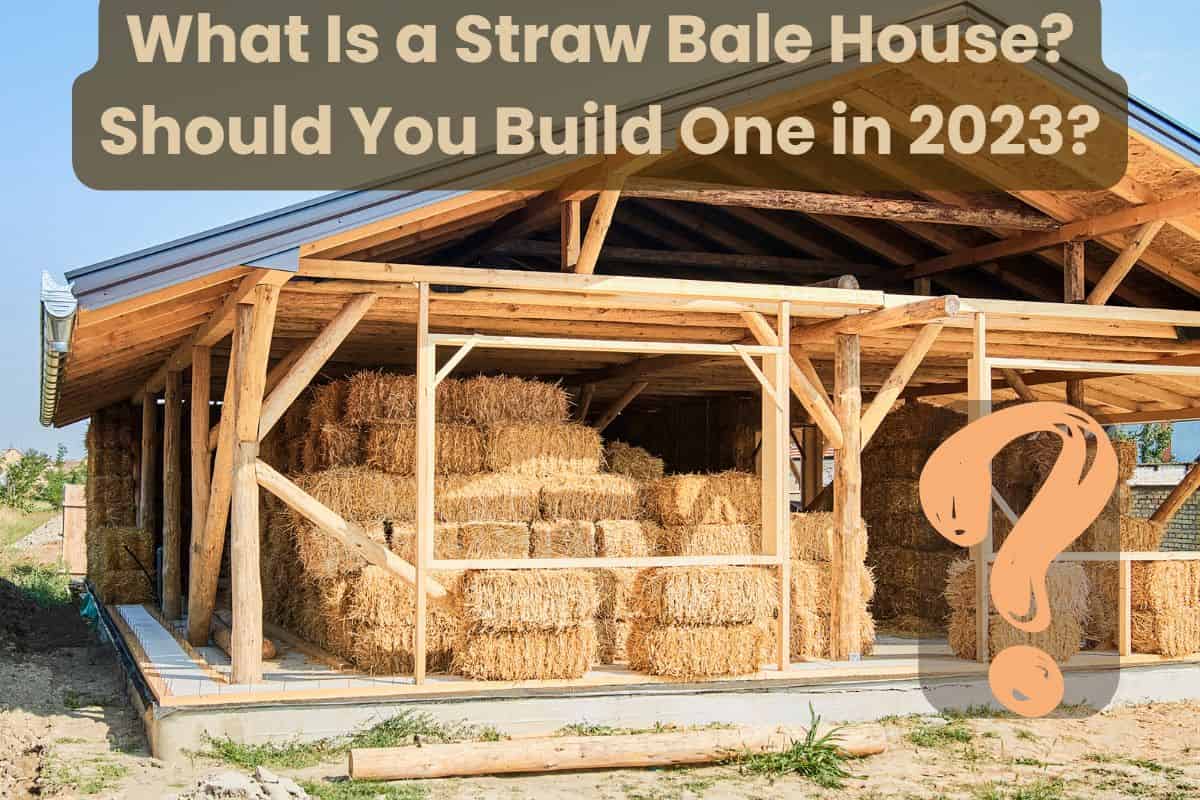

What Is a Straw Bale House? Should You Build One in 2023?

Straw is one of the green building materials that help counter the construction industry’s environmental impact.

Building a straw bale house may seem impractical, given the story of the three little pigs, and since only a few houses today are made from this material.

However, before dismissing it, you should look closer at straw bale house construction. You might be surprised at the answers to questions like, “What is a straw bale house? Should you build one in 2023?”

The walls of a straw bale house are made from straw. In some cases, straw bales are used as the primary structural material, but in others, they are supported by a wooden frame. Straw bales provide excellent thermal insulation and are a sustainable, natural material.

I’ll take you through the details of straw bale houses in the rest of this article.

I’ll discuss the techniques used, including the pros and cons of straw bale construction to help you make an informed decision.

Let’s get started!

The Genesis of Straw Bale Construction

The scarcity of straw bale houses today doesn’t mean this is an emerging construction technique.

Straw bale construction began in Africa during the Paleolithic era. In this era, straw was employed for strengthening earthen walls and improving insulation.

In Germany, straw bale construction dates back 400 years, when the loose material was used to build grass-thatched roofs.

In America, the technique is attributed to European settlers who used it to insulate their teepees. The Schoolhouse in Nebraska, built between 1896 and 1897, is the first documented evidence of straw bale construction in the U.S.

Straw bale construction gained popularity in the U.S. in the 1890s after the invention of the mechanical hay baler. This invention made it easier to access straw bales for construction.

Straw bale houses in Europe and America have existed for more than 100 years.

The most commonly used straw bales are rice, wheat, oats, and rye. However, other bales, such as those made from millet, barley, flax, and hemp, have also been used in straw bale construction.

What Is a Straw Bale House (Construction Techniques)?

There are three techniques used in straw bale construction:

- Load-bearing (Nebraska style)

- Post-and-beam infill

- Prefabricated cassettes

Let’s take a look at each technique and how it’s used.

Load-Bearing (Nebraska Style)

The load-bearing straw bale construction is also known as the Nebraska style because the first straw bale builders in the Schoolhouse of Nebraska used it.

This technique uses straw bales as the primary structural material to support the roof. It means there are no beams, and the straw walls support the load.

The straw bales are laid in courses above each other until the desired height is achieved. These bales are laid carefully so that each bale goes at the center of the bale joint beneath.

A point worth mentioning is that straw is biodegradable and can easily rot when it comes into contact with ground moisture. Therefore a brick plinth is used to raise the bales off the ground to prevent contact with moisture.

The following considerations come into play when laying the straw bales:

- Bale Slippage: It’s easy for straw bales stacked on top of each to slip and move around. To prevent this, the brick plinths are fixed on a base plate with wooden spikes that hold the bales in place.

- The structure’s stiffness: The bales are pinned onto each other to make the wall firm and ensure the building remains stiff throughout its lifecycle.

- Structural integrity: The house must maintain the optimum safety level when supporting the intended load. This is achieved by ensuring the bales are tightly packed and compressing them using ratchet straps, making it easier to proceed to the next stage.

- Door and windows: Any opening in a straw bale building is susceptible to water damage. Therefore, the doors and windows are installed close to the wall’s external face.

Although this approach requires fewer construction skills and resources, it has the following drawbacks:

- Insufficient load-bearing strength: You can only build a one-story structure due to the inadequate load-bearing capability of the stacked straw bales.

- Limited wall length: Building ratios dictate that unsupported walls should not exceed 25 feet (7.62 meters) in any direction. Thus, since the Nebraska technique doesn’t incorporate supporting beams for the walls, building a wall that exceeds 25 feet (7.62 meters) is against safety building codes.

- Limited space for windows and doors: The total space for doors and windows can never exceed 50% of the wall’s surface area. This means you can only have a few doors and windows in your house.

Expert Advice: It’s advisable to avoid metal framing when using this technique to prevent thermal bridges within the straw. Thermal bridges within the straw bales cause the accumulation of moisture that eventually damages the structure’s integrity.

Post-and-Beam Infill

In this technique, a post-and-beam structure is used to support the roof. Straw bales are added in between for insulation purposes.

Unlike the Nebraska style, this technique saves time since you don’t have to stack each bale to attain the desired wall height.

Attaining sufficient wall compression remains a challenge in this technique. Despite using ratchet straps to ensure the bales are tightly packed, extra care must be taken to ensure the bales don’t move out of place.

The following approaches are employed to ensure sufficient wall compression:

- Positioning and tightening: The straw bales and the wall plates are positioned within the supporting frames before being lowered to the desired location. Once in place, the straw bales are tightened to attain the optimum compressive strength.

- Compressing the penultimate layer: Once the bales are in place, the penultimate layer is compressed before adding another layer of straw bales.

Unlike the Nebraska technique, the post-and-beam infill permits more stories and opening spaces due to the beams supporting the walls. Therefore, you can have many doors and windows and extend the wall’s length past the 25-foot (7.62-meter) threshold.

Prefabricated Cassettes

In this technique, prefabricated cassettes are used in between load-bearing walls for insulation purposes.

These cassettes are designed and constructed off-site and shipped once ready. This makes the erection process faster and easier since you don’t have to stack individual bales on top of each other.

The cassettes are designed using various materials, such as wood, straw, or hemp, depending on the exact needs of the structure.

Prefabricated cassettes provide excellent thermal insulation, thanks to the air-tight compartments that don’t leak out warm air during winter.

Straw Bale Construction Building Codes

According to FEMA, building codes are in place to ensure safe and resilient structures. These codes stipulate the minimum design and construction requirements to be met before the structure is deemed safe and fit for human habitation.

A point worth mentioning is that construction codes vary from state to state and country to country. Therefore, if you plan to build a straw bale house, you should confer with the relevant authorities to familiarize yourself with the building codes.

In Texas, for instance, the following codes apply to straw bale construction:

- Shape: The bale must be rectangular.

- Size: The bale’s height and thickness should always be at least 12 inches.

- Moisture content: It shouldn’t exceed 20 percent of the bale’s weight when the first layer of plaster is applied.

- Density: The bales’ dry density must be at least 6.5 pounds per cubic foot (104 kg/cubic meter).

- Type of straw: The bales should only be from wheat, rice, oat, rye, and barley.

You can access these and other straw bale construction codes in Texas from the International Residential Codes.

How to Construct a Straw Bale House

Constructing a straw bale house involves the following steps:

Step 1: Deciding on the Technique

We’ve already discussed the three techniques you can use to build your straw bale home. Therefore, the first step is to decide which of the three to use.

It’s important to choose a technique that will fit your budget and building needs. Some things to consider include the following:

- Your desired wall length

- The number of stories you want

- The number and size of the doors and windows

Step 2: Deciding on the Type of Straw Bale

There are two main types of straw bales:

- Two-string bales: These are tied with two wires or twines. They have a dimension of 18 inches by 14 inches by 36 inches and weigh between 50 and 60 pounds (22.68 and 27.22 kg).

- Three string bales: Are tied with three wires or twines. They have a dimension of 23 inches by 16 inches by 42 inches and weigh between 75 and 80 pounds (34.02 and 36.29 kg).

Step 3: Constructing the Foundation

It’s recommended to use concrete footings for all straw bale structures to prevent contact with ground moisture.

Whether you’re building with the Nebraska style, post-and-beam infill, or prefabricated cassettes, the foundation must be deep enough to sustain the load above.

After building the foundation, stack the bales above each other to attain the desired height for the load-bearing style. Afterward, erect a roof frame and assemble the roof.

For the post-and-beam infill, start by constructing structural elements like roof, frame, and foundation. After that, use straw bales to fill in between the spaces.

Remember to raise the straw bales a few inches from the ground to prevent moisture penetration in both cases.

Step 4: Applying a Moisture Barrier

Once the straw bale wall is in place, apply a moisture barrier outside using stucco cement, plasters, or gypsum plasters.

This keeps the straw bales dry and protects them from potential water damage.

Step 5: Applying a Final Layer of Plaster

Finally, apply plaster made with cement, lime, or clay to your structure’s exterior. This final layer increases the house’s thermal mass and gives it the desired finish look.

If you don’t want this top layer to serve as the topcoat, you can apply a final layer of paint in your desired color.

Advantages and Disadvantages of Straw Bale Construction

Constructing a straw bale house has the following advantages and disadvantages:

Advantages

- Excellent insulation: The R-value of straw bale walls ranges from 17 to 54. Such a high R-value means that the thick walls offer superior insulation to keep the interior warm during winter and cool during summer. They also offer excellent soundproofing.

- Cost-effective: Building a straw bale house is cheaper than traditional building methods that use wood and concrete. Straw is a waste arising from the agricultural industry and will not cost as much as other building materials.

- Low fire risk: Straw bales are packed tightly, reducing airflow and improving fire resistance.

- Renewable material: Straw is renewable, so your construction will have a minimal environmental impact.

Disadvantages

- Lack of code acceptance: Some states don’t account for straw bales in their codes, impairing the use of these materials.

- Moisture and pets: Straw bales can be susceptible to moisture and pest damage.

- Maintenance: The house requires regular repairs to keep it safe and free from water damage.

Final Thoughts On Building With Straw Bales

Why should you build a straw bale house?

You should build a straw bale house because it’s sustainable, eco-friendly, and less expensive than using conventional building materials.

It also offers excellent insulation, improving energy efficiency and saving you money in heating and cooling bills.

Moreover, the renewable nature of straw makes it an excellent choice for eco-conscious homeowners.

However, before building a straw bale house, check your local building codes and ensure you comply.

Now that you know what a straw bale house is, check out these 9 healthiest renewable building materials you can use today.