Is Steel Recyclable? The Surprising Truth About Green Steel

Is steel recyclable? It’s a question many of us might have pondered as we consider the environmental consequences of steel consumption in construction.

As engineers, contractors, architects, builders, and homeowners, we want to know whether we can recycle steel to promote sustainable construction.

Steel is 100% recyclable because it retains its properties after being recycled. As an iron alloy, steel maintains its tensile strength, durability, and corrosion resistance even after multiple recycling. Thus, recycled steel doesn’t compromise the structural integrity of engineering projects.

In the rest of this article, I’ll discuss the sources of recycled steel and the recycling process. I’ll also discuss where you can use recycled steel in construction. Keep reading!

Steel Recycling Facts

Seventy percent of all the steel ever manufactured is still in use today, thanks to recycling adoption.

But what does that look like in terms of recycling rate?

The global steel recycling rate is over 60 percent, explaining why most ever-produced steel is still in use.

Recycling steel promotes green building due to its energy conservation and lower greenhouse gas emissions.

The recycling process conserves between 60 and 74 percent of the energy used to produce steel from raw materials. It also conserves the environment by generating less air pollution.

According to the Bureau of International Recycling, there is higher steel scrap usage in many countries due to the increasing adoption of steel recycling.

Moreover, external steel scrap trading has received a massive boost, as evidenced by its increase to 109.6 million tonnes in 2021.

There has been an increase in the use of steel scrap, the raw material for green steel production, between 2017 and 2021.

As of 2019, 630 million tonnes of scrap steel was recycled annually. This reduced carbon emissions from steelmaking by nearly 950 million tonnes annually.

Besides reducing greenhouse gases, recycled green steel helps conserve iron ore, limestone, and coal.

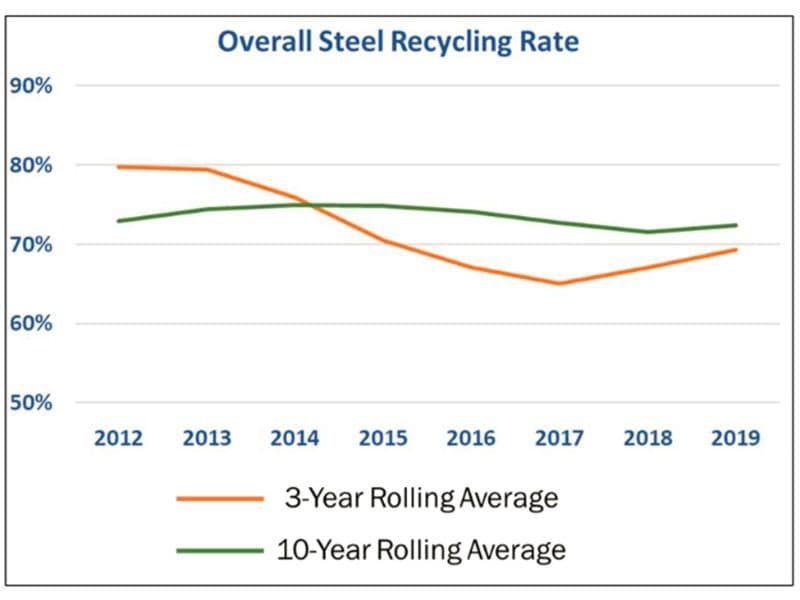

The graph below demonstrates steel recycling rates in the U.S. (end-of-life scrap and new scrap):

The rate of steel recycling is higher in the construction sector than many other manufacturing sectors in the U.S., as shown in the table below, which presents data for 2019 from the American Iron and Steel Institute and Steel Manufacturers Association.

| Sector | 2019 Steel Recycling Rate |

| Structural sections in construction | 97% |

| Automotive | 96% |

| Appliances | 78% |

| General construction | 74% |

| Other construction components | 68% |

| Containers | 62% |

| Rebar from construction | 59% |

| Others | 46% |

Table 1: Sector-specific steel recycling rates in the U.S. Source: American Iron and Steel Institute and Steel Manufacturers Association

Sources of Recycled Steel

Recyclers obtain scrap steel for recycling from a range of sources, including:

- Hot-rolled steel bars and beams that are used as structural elements in construction projects.

- Automotive parts like car frames, engines, and axles.

- Construction materials such as columns, beams, and frames.

- Household appliances like dishwashers and washing machines.

- Miscellaneous items like cans, nails, wires, and bicycle parts.

- from manufacturing processes in warehouses and factories.

Steel scrap from the above sources is collected by scrappers and taken to steel recycling yards.

The Steel Recycling Process

Steel recycling is a stepwise process that must be done correctly to retain the material’s properties for reuse.

Adhering to the steel recycling process guidelines helps ensure all recycled steel materials are contaminant-free.

If you want to know how to recycle steel, here are the steps to follow:

1. Collection

The first step is collecting steel from different sources for recycling.

The common steel collection methods include:

- People taking their unwanted steel products to recycling firms.

- Scrappers collecting steel materials and taking them to recycling companies.

- Steel recycling plants collecting scrap from manufacturing processes.

2. Sorting and Separating

Once the scrap steel arrives at the recycling yard, it’s sorted based on color, quality, weight, and product type.

Moreover, recycling yards use the sorting opportunity to separate ferrous materials (containing iron) from non-ferrous ones (not containing iron). This separation helps determine the best way to recycle the materials.

Ferrous materials include stainless steel, iron alloys, and the steel commonly used in structural members. On the other hand, non-ferrous materials include tin, gold, and copper.

3. Crushing and Shredding

Scrap steel materials are delivered in pieces of different shapes and sizes.

Large materials occupy more space on the conveyor belt and take longer to melt. Therefore, they are shredded to smaller sizes before recycling.

The shredding process prepares the material for melting by turning it into smaller pieces that can melt quickly.

4. Melting

The shredded pieces are transferred into a large furnace with high temperatures exceeding 3,500°C (6,332°F) for melting.

The melting process is necessary for liquefaction and burning off any impurities before creating metal sheets.

The resulting sludge-like material undergoes purification to improve quality.

Steel recycling yards use magnetism and electrolysis processes to purify the molten content.

Electrolysis entails using electricity, water, and metals to extract impurities. On the other hand, magnetism uses magnets to separate the slag and metals based on their magnetic strength.

5. Solidification

The pure molten liquid goes into a separate room for cooling and solidification.

The material is rapidly cooled in water or oil to solidify it as steel bars or pieces. The resulting products are then tempered (soaked at a lower temperature) to eliminate any internal stresses due to solidification.

Finally, recycling plants mold the steel into sheets, blocks, and other shapes for easy transportation.

6. Quality Testing

Steel recycling companies use physical and chemical tests to determine the material’s quality.

Chemical tests include x-ray fluorescence and spectroscopy, while physical tests involve tensile strength and hardness measurements.

7. Transportation

After ascertaining the material’s quality, the next step is transporting it to manufacturing plants for reuse.

Steel recycling companies use different means, including ships, trucks, and railcars, for transportation. The mode of transport depends on the quantity of steel scrap being transported.

Where to Use Recycled Steel in Construction

As mentioned, recycled steel retains its tensile strength, making it ideal for construction projects.

Here are some of the common places to use recycled steel in construction:

- Making girders, frames, and columns in large structures, including bridges and buildings.

- Facade cladding on exterior walls.

- Steel framing for doors and windows.

- Steel mesh reinforcement for concrete foundations, beams, and slabs.

- Roofing purlins, sheets, and girts.

- Steel decks for supporting concrete floor slabs.

It’s worth mentioning that recycled steel is among the most cost-effective, sustainable building materials you can use in construction.

So, Is Steel Recyclable?

If the question, “Is steel recyclable?” was on your mind, you now have the answer.

Steel is a highly recyclable material that can be reused without compromising its tensile strength.

Recycled steel is a more eco-friendly material than virgin steel and helps reduce a construction project’s carbon footprint.