Recycled Steel: 5 Benefits of Recycled Steel in Construction

According to the World Steel Association, steel is the most recycled material worldwide, with 680 million tons recycled in 2021.

The use and material efficiency rate of recycled steel reached 97.34% in 2021. This is due partly to the many benefits of recycled steel in construction.

Recycled steel earns its right to be included in the list of sustainable building materials because it conserves energy that would have otherwise been used to produce virgin steel.

Moreover, recycling steel eliminates waste and emissions from extracting iron ore, coal, and limestone. Taking into account all these factors, recycling steel conserves between 60 and 74% of the energy used to produce new steel.

In this article, I’ll cover steel recycling and its benefits in the construction industry. You’ll learn about the various ways that recycled steel fosters eco-conscious construction, so keep reading!

Recycled Steel: Background

Why is steel good for construction?

Steel is a widely used metal in construction due to its excellent durability, resistance to corrosion, and high tensile strength.

Although concrete, bricks, soil, and the like account for most construction and demolition (C&D) waste, steel is the most common form of metal C&D waste.

Luckily, many steel components can be recycled without losing strength.

Most countries promote steel recycling to save energy and conserve their natural resources. This explains why the 13th Edition of the World’s Steel Recycling Report shows increased steel scrap and decreased crude steel production for most countries.

According to the report, the world’s annual scrap steel use remained between approximately 67 and 73 million tonnes between 2017 and 2021, suggesting that many companies and builders leverage recycled steel in construction and other activities.

External scrap steel trading also increased to 109.6 million tonnes in the same period.

According to the report’s 2019 data, 630 million tonnes of steel was being recycled annually.

This recycling rate was responsible for saving approximately 950 million tonnes of carbon dioxide emissions annually due to steel manufacturing.

Countries and economic blocs such as the U.S., the E.U., Russia, and the Republic of Korea have witnessed a rise in steel recycling and use of scrap steel, as shown in the table below. However, China is a notable exception, slightly decreasing its use of scrap steel.

| Steel Scrap Consumption | |||

| 2021 | 2020 | % Change (2020-21) | |

| China | 226.21 | 232.62 | -2.8 |

| EU-27 | 87.853 | 75.255 | 16.7 |

| USA | 59.4 | 50.2 | 18.3 |

| Turkey | 34.813 | 30.077 | 15.7 |

| Japan | 34.727 | 29.179 | 19.0 |

| Russia | 32.138 | 30.030 | 7.0 |

| Republic of Korea | 28.296 | 25.831 | 9.5 |

Steel scrap consumption in million tonnes. Source: BIR Global Facts and Figures

What is the recycling rate for structural steel used in construction?

According to the American Institute of Steel Construction, although steel is 100% recyclable, the proportion of recycled steel found in members used for construction is 93% worldwide.

Steel Recycling

While all steel can be recycled, the process varies based on the product. However, the basic steel recycling process entails the following steps:

- Collection: Collecting scrap steel from different sources, such as old cars, appliances, and buildings. In many cases, end users put this scrap in designated bins for collection by the contracted recycling firm. A few end users might transport the metals to the recycling plant.

- Separating: To reduce contamination, the recycling plant uses magnetic equipment to separate recyclables from non-recyclables in the scrap metal stream. This is a crucial quality control measure to maintain recycled steel’s purity, strength, and durability.

- Shredding: Specialized machines are used to crush and break the metal into smaller pieces to make processing more efficient. Working with smaller steel pieces helps the plant reduce energy use and costs.

- Smelting: The shredded metal pieces are transferred into a furnace at high temperatures, usually over 3,500°C (6,332°F) for smelting. Fluxing agents are also added to remove impurities.

- Refining: This process is essential for quality control purposes. It removes impurities affecting recycled steel quality.

- Solidifying: The refined melted steel is transferred to cooling containers and solidified into steel ingots or blocks.

- Rolling: The cooled ingot is cut and rolled into different shapes for various uses, such as making furniture, kitchenware, automotive components, and construction products.

- Testing: Quality tests are conducted on the finished products using quality control tools like spectrometers, hardness testers, and ultrasonic testing equipment. These tests guarantee the recycled steel’s durability, strength, and corrosion resistance.

Benefits of Recycled Steel in Construction

Using recycled steel in construction is rising as more people embrace green building techniques to reduce their projects’ carbon footprints.

Besides being environmentally friendly, engineers, builders, contractors, and homeowners use recycled steel for its multiple benefits in construction.

Let’s look at the main benefits of recycled steel in construction:

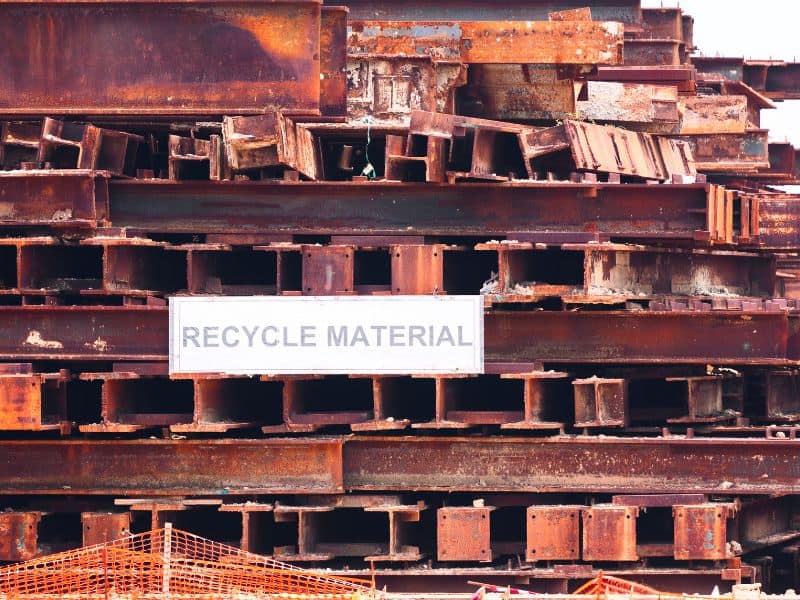

1. Waste Management

Construction is among the most wasteful industries globally.

Approximately 13-60 percent of the total waste sent to landfills worldwide yearly is C&D waste, and recycling steel for construction is an excellent way to reduce this landfill waste.

It’s worth noting that structural pieces like columns and beams can be re-used in construction without being re-melted. Therefore, instead of sending these components into landfills, consider reusing them on-site for other projects.

2. Cost Savings

Using recycled steel in construction is more cost-effective than its virgin counterpart.

Recycling steel reduces production costs because it requires less energy, labor, and raw materials.

Recycling eliminates the cost of disposing of C&D waste in landfills and sourcing virgin steel for construction.

It’s worth noting that although recycled steel is cheaper, it’s of excellent quality, ideal for construction.

3. Durability & Strength

The recycled steel used in construction is as strong and durable as its virgin counterpart. It retains its tensile strength even after many recycling cycles.

Moreover, the material maintains its weight-bearing capacity, an essential feature for structural and foundational pieces.

Recycled steel is corrosion-resistant, making it ideal for building frames and flooring in hazardous environments.

4. Sustainable Construction

Building with recycled steel contributes to sustainable construction because the material conserves energy and minimizes carbon emissions.

To put that into perspective, recycling one “steel food can” saves enough energy to power a 10-Watt LED bulb for over 24 hours. Therefore, imagine how much energy you’ll conserve using recycled steel in construction.

You also reduce your project’s carbon footprint by reducing iron ore extraction and avoiding using coal and limestone to produce new steel.

5. Versatility

Recycled steel is highly versatile for construction needs. It can be molded into different shapes for various building projects, including buildings, roads, dams, and bridges.

The material is also ideal for making pipes used in plumbing and sanitation systems.

Overall, architects and engineers have much to gain by using recycled steel in construction over virgin steel.

Not only will the environment benefit from your effort, but you’ll also reduce costs without compromising quality or strength. Therefore, it’s a win-win situation.

What Is Steel Work in Construction?

Steel work in construction involves shaping and joining steel pieces to form structural components for buildings, bridges, dams, roads, and other engineering projects.

Steelwork may involve welding steel frames or fixing bolts on supports. In some cases, it may include fabricating new steel components from scratch.

The task requires precision and attention to detail to meet all construction safety standards.

For non-structural applications, steelwork includes metalwork like furniture making, sculptures, railings, and grills.

It’s worth noting that steelworkers need professional knowledge to read construction plans accurately. They must also understand the engineering specifications for each project to ensure good quality.

Final Thoughts

Recycled steel is an essential building material for environmental conservation. It’s also cost-effective, durable, and strong.

Building with recycled steel helps reduce the amount of C&D waste that gets into landfills, minimizing pollution.

Moreover, since the recycling process conserves energy, the material helps reduce carbon emissions from manufacturing new steel. Therefore, embrace recycled steel if you want your project to be eco-friendly.

Remember to employ experienced steelworkers to fabricate and install steel components — the process requires precision and attention to detail.