Check Out These 8 Recycled Plastic Building Companies

Building with plastic is one way to reduce the environmental impact of these products and can divert them from ending up in oceans and landfills.

However, since most building companies specialize in conventional construction that uses concrete and steel, it can be challenging to find one that relies on recycled plastic.

Although fewer recycled plastic building companies are available, examples have been popping up worldwide, providing a much-needed eco-friendly option.

According to the UN Environment Program, about 7 billion tonnes of plastic products manufactured between 1950 and 2017 became waste and ended up in landfills or released into the environment.

Therefore, as an environmentally-conscious person, you can make a difference by patronizing companies that use recycled plastics in their construction. They are the ones leading the way toward a cleaner and greener future.

In the rest of this article, I’ll discuss eight recycled plastic building companies you should know about. They help create a more habitable planet by leveraging sustainable construction practices that use recycled plastics.

Let’s get started!

1. JD Composites

This is a construction company based in Nova Scotia, Canada. It specializes in building using foam core made from 100% recycled plastics.

JD Composites is a company that aims to improve environmental quality by using plastic bottles in its construction processes. By doing so, it seeks to reduce the amount of plastic that pollutes our oceans and land.

The company aims to revolutionize traditional construction processes through patented structural insulated panels (SIPs) and uses SIPs made from 100% recycled PET plastic.

To overcome the misconception that plastic panels are weaker, the company tested its products to ensure they were durable before use in construction.

A test conducted by Element Materials Technologies in Ontario proved that the panels were stronger than many assumed and could withstand a 326 mph (524.65km/h) wind.

The company’s unique building process creates cost-effective, environmentally friendly, and structurally superior houses.

2. Conceptos Plasticos

Conceptos Plasticos is a company founded by architect Oscar Mendez in Bogota, Colombia. The company builds low-cost houses from recycled plastic. Each house is approximately 430 square feet (39.95 square meters).

Conceptos Plasticos recycles and transforms plastic into Lego-like bricks by melting and molding them into the desired shapes. The bricks are also made from recycled sheets of plastic, which are then cut into strips that fit together like Lego pieces to create the walls.

The company’s concept is to build affordable housing with an environmentally-friendly approach. It has the following operating principles that make it unique:

- Environment: To promote a recycling culture among communities and preserve the environment.

- Social: To enhance the work and dignity of recyclers by fostering positive labor practices and empowering communities through technological education on waste management.

- Economic: To enhance entrepreneurial skills in communities and fair trade among traders and recyclers.

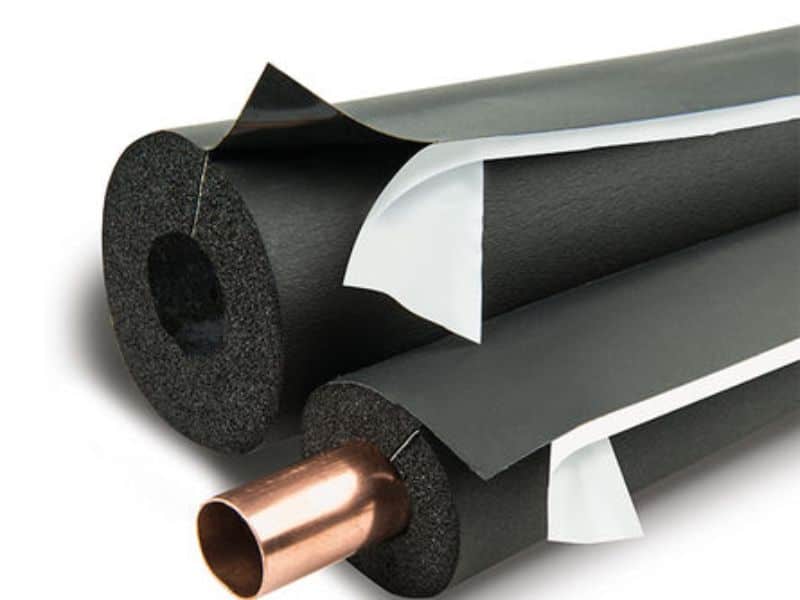

3. Armacell

Armacell is a North Carolina-based company specializing in producing sustainable building materials. It focuses on products that increase insulation in residential and commercial buildings and industrial applications.

Of particular interest are their recycled plastic products used in construction. The company produces PET composite foam for use in high-performance building structures.

The foam core is made from post-consumer recycled food and beverage containers that have been ground, melted, and reformed into sheets.

The company’s PET composite foam board is ideal for insulation, soundproofing, and other projects such as wall cladding and decking.

With an impressive ratio of density to stability, the company’s PET foam board is lightweight, flexible, and stable. It’s suitable for green buildings that aim to save energy consumption.

The PET foam is suitable for applications such as:

- Wind energy

- Building and construction

- Transport

- Marine

- General industry

The unique feature of this recycled plastic building company is that it manufactures lightweight yet strong core foams. These core foams are suitable for structural and insulation purposes, making Armacell one of the leading firms in energy efficiency.

4. Gjenge Makers

Gjenge Makers is a recycled plastic building company based in Nairobi, Kenya. The company recycles plastic into pavers as an alternative, affordable, and sustainable construction material.

Gjenge Makers uses plastic as the binder and sand as the aggregate to make polymer concrete. The company creates a sturdy material equivalent to Portland cement by combining recycled plastic and sand.

The pavers are made by mixing crushed plastic, sand, and color pigment. The mixture is then fed into an extruder and heated to approximately 400°C (752°F).

The pasty compound that leaves the extruder is shaped into molds of varying shapes and sizes and compressed by a hydraulic press into pavers.

The company’s primary goal is to reduce the amount of plastic waste in Kenya by converting it into an affordable construction material. The organization has created employment opportunities for locals, especially women, and encourages them to use recycled plastics as an income-generating activity.

Gjenge Makers’ unique feature is converting weak plastic into a sturdy construction material by mixing it with sand aggregate. The company makes its pavers up to seven times stronger than conventional concrete by pressing them to remove air pockets.

5. Shini USA Plastic Construction Materials

The Shini USA is a division of Budzar Industries that specializes in the production of plastic processing and plastic recycling machinery. It aims to make plastic recycling and processing for construction processes easier.

Shini USA produces equipment to make recycled plastic products for construction, such as panels, tiles, and rods.

The company is unique because it offers material testing, quality control checks, and excellent support to ensure clients get high-quality products and services.

Some plastic recycling and processing machines you can get from this company include:

- Plastic granulators

- Hot oil systems

- Honeycomb desiccant dryers

The company offers the best prices to fit most customer budgets for plastic processing machinery that gets the job done quickly, efficiently, and to a high standard.

6. EcoDom

EcoDom is a recycled plastic construction company based in Mexico.

Carlos Daniel Gonzalez, the company’s founder, was motivated by Mexico’s yearly production of approximately 800,000 tons of plastic waste and the fact that only 15% of this waste is recycled.

The company aims to address Mexico’s plastic waste disposal problem by recycling and transforming plastic into construction materials.

It recycles everything from PET bottles, plastic sheets, and wrappers to create blocks for building walls, roofing, and structural beams.

The company focuses on sustainable construction to preserve the environment and protect human health.

Its unique feature is offering living quarters at lower cost while reducing waste and transforming lives.

You can rely on the company for the following:

- Thermal walls

- Concrete roofing

- Thermal roofing

- Structural beams

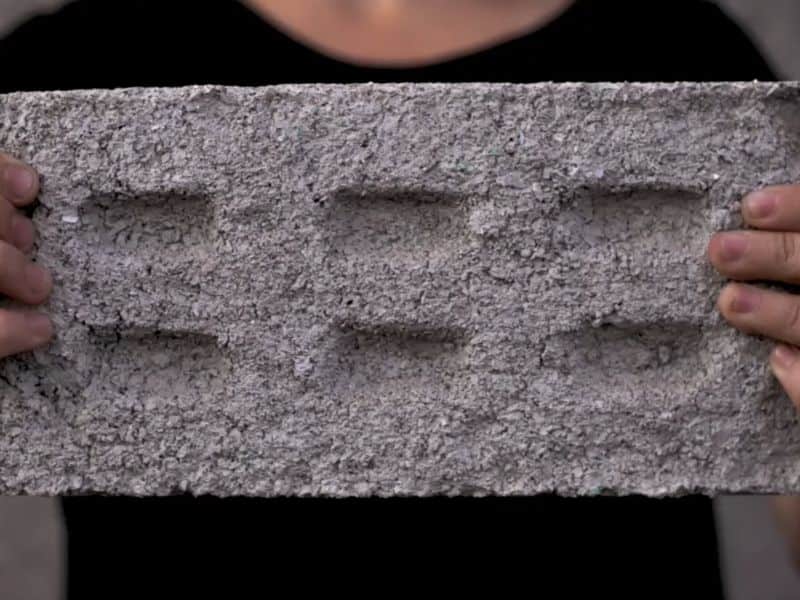

7. Fundación Eco-Inclusión

The Eco-Inclusion Foundation is an Argentina-based organization that produces plastic-based ecological bricks.

The organization focuses on reducing plastic waste and improving livelihoods by transforming plastic waste into building materials.

It collects post-consumer and industrial plastic, which is then recycled and processed to produce bricks of different sizes with the same characteristics as traditional bricks.

The organization also helps to create employment opportunities for people living in impoverished areas by offering training on how to recycle plastics and use them in construction projects.

The organization collects plastic to make bricks from 45 plastic-collection sites. They use approximately 20 bottles to make one brick.

The organization uses a unique remodeling technique that produces plastic bricks with similar features to their traditional counterparts.

An important advantage of these plastic-based bricks is that they are lighter than conventional bricks and easier to use in construction.

8. The Plastic Flamingo

The Plastic Flamingo is a plastic-recycling company based in the Philippines. It was founded by Francois and Charlotte Lesage, who wanted to convert the enormous amount of plastic waste in the Philippines into building materials to help solve the housing shortage there.

The company uses recycled plastic to produce:

- Eco lumber

- Eco boards

- Pellets

Final Thoughts On Recycled Plastic Building Companies

These eight recycled plastic building companies are paving the way for a sustainable future.

By transforming plastic waste into durable and innovative building materials, they are reducing the amount of plastic in landfills and oceans.

With the growing demand for cost-effective and eco-friendly building solutions, these companies are proving that recycled plastic is a viable alternative to traditional materials.

Besides recycled plastic, you may be interested in other sustainable construction techniques. Here is an article with awesome examples of using sustainable construction.