What Is Rammed Earth Construction (vs. Conventional Builds)

Rammed earth construction is a sustainable building technique that is as old as time.

Instead of using energy-intensive concrete and other non-renewable materials, rammed earth construction relies on readily available soil.

As a concerned homeowner, you may have questions like, “What is rammed earth construction?” And “How does it differ from conventional building methods?”

Rammed earth construction is a technique for constructing floors, walls, and foundations by ramming aggregates such as chalk, earth, gravel, and silt into a formwork. For modern rammed earth construction, a small amount of cement is added to the mixture as a stabilizer to make it more durable.

In the rest of this article, I’ll discuss the history of rammed earth construction, including how this technique was used in the Great Wall of China.

I’ll also compare rammed earth construction with conventional methods to help you understand the difference.

Let’s get started!

If you’d like to learn about whether rammed earth is a good flooring material, you should read our article “Can You Use Rammed Earth For Floors? (See These 5 Examples)” which covers this subject in depth.

The History of Rammed Earth Construction

The traditional rammed earth construction method has a rich history that dates back to 5,000 BCE. The Neolithic period has strong evidence that people used rammed earth as a construction material.

During the Neolithic era, the Yangshao people of China used water, clay, sand, and lime to build walls and foundations.

Due to their availability, these were the most viable construction materials in this culture. The presence of the Yellow River made ramming soil into formwork easy as it provided a continuous water supply.

The basic rammed earth architecture in China at that time involved heaping rammed earth against a single vertical timber wall as formwork.

The discovery of small wooden boards used as formworks in the Lung-shan settlement of Pingliangtai is solid evidence for the use of rammed earth during the Neolithic period.

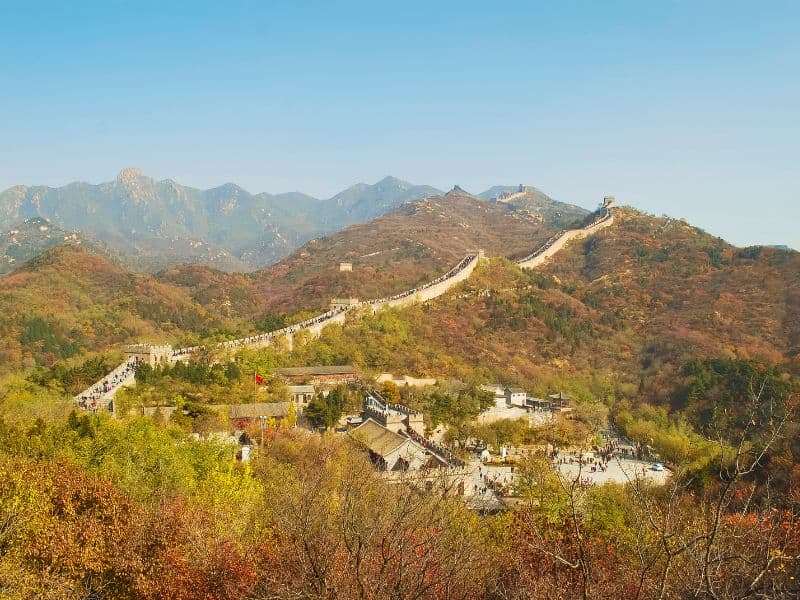

The Great Wall of China is one of the most significant structures built with rammed earth in China.

The wall dates back to the 5th century BCE and was made from soil and gravel with some lime added for stability. This construction method was based on hangtu, an ancient Chinese wall-building technique.

Constructing the Great Wall of China involved pouring earth and gravel into removable wooden shutters. After pouring, the mixture was tamped down layer by layer until it reached the top of the wall. Finally, the wall was capped with a layer of bricks.

Suffice it to say, only the early sections of the Great Wall of China had rammed earth. These were the sections built during the Qin and Han dynasties, as well as the Warring State era.

Over time, rammed earth technique evolved and made its way to other regions in Asia, Africa, America, and Europe.

In Africa, Egypt has solid evidence of rammed earth construction during the Pharaoh Kingdom in 3,000 BCE.

During this kingdom, Egyptian cities were made of rammed earth (pisé de terre). For instance, the walls of famous pyramids in Egypt, such as the Great Pyramid of Giza, were made of rammed earth.

In the United States, the history of rammed earth constructions dates back to the 1800s. The book “Rural Economy” by S.W Johnson includes several references to using rammed earth as a construction material in this region.

The iconic Church of the Holy Cross in Stateburg, South Carolina, and Borough House Plantation are historic landmarks made of rammed earth.

In Canada, St. Thomas Anglican Church in Shanty Bay, Ontario, was built between 1838 and 1841 using rammed earth material.

Rammed Earth Vs. Conventional Construction

The rammed earth construction method fell out of use after World War II as the prices of conventional building materials like cement and steel dropped. At this time, people considered rammed earth substandard, necessitating its relegation to rural areas.

However, in recent years, rammed earth construction is again gaining popularity due to its sustainability and eco-friendliness.

The rammed earth technique uses local materials that are available in abundance. Moreover, rammed earth does not require energy-intensive plant equipment or fossil fuel burning.

On the other hand, conventional wall materials require more energy for production and transportation to construction sites. For example, according to Science Direct, producing a ton of cement consumes 3.4 GJ of thermal energy or 110kWh of electricity.

What’s more, rammed earth is easily recyclable. For instance, once a rammed earth building is demolished, the material is easily broken down into fine soil particles before disposal or used in producing new rammed earth buildings.

On the contrary, since most conventional building materials are hard to recycle, they contribute immensely to land pollution. For instance, concrete accounts for 35.4% of construction and demolition wastes in landfills.

The only downside of rammed earth construction is its susceptibility to water and low compressive strength. However, modern rammed earth walls have ways to deal with these challenges, including:

- Using cement-stabilized rammed earth: Using 5 to 10% cement to stabilize rammed earth increases its compressive strength from 2.68 MPa to about 9.30 MPa. A 9.30 MPa compressive strength is sufficient for the finished walls to bear loads of up to 2 to 3 stories.

- Curing stabilized rammed earth properly: You should cure cement-stabilized rammed earth for at least 28 days to harden and prevent water absorption.

- Protecting the basement from water: You should install waterproofing material like mortar in the basement or foundation of a rammed earth structure.

The Basic Structure of Rammed Earth Walls

To help you understand how rammed earth walls are built, I’ll take you through its basic structure below:

Formwork

Like certain types of conventional construction, rammed earth requires formwork to form the material into the desired structural shape. The formwork is made with bamboo, wood, plastic, or metal.

If made with steel, the formwork is usually covered with plywood to create an off-form finish for different sections, which transfers the pattern of the wood grain to the concrete for a more pleasing look.

The Base Layer

The base layer is a layer of gravel and sand, preferably with stabilizer such as Portland cement to add strength, that helps protect the formwork from damage when adding the rammed earth material. The base also helps disperse water evenly over the foundation while providing lateral stability.

Rammed Earth Mixture

There are two types of rammed earth mixture – raw and stabilized. The raw mix comprises aggregates like sand, clay, gravel, chalk, and silt. In terms of composition, sand makes up the highest percentage, between 60 and 70%.

Stabilized rammed earth mixture has a binder in addition to the basic raw materials. Cement and lime are the commonly used binders.

Compacting and Dampening the Rammed Earth Material

Once the mixture is ready, it’s time to fill up the formwork. The material is usually moistened before filling to ensure optimal strength and density when tamped down.

Most people use a shovel to fill the formwork with the mixture as it helps prevent wastage.

The compaction process requires mechanical or manual tamping with a hand-held or pneumatic tamper. In the process, excess material is scraped off and any weak spots reinforced with steel or bamboo.

After compacting, the rammed earth structure is left to dry for about 14 days to reduce cracking due to thermal shock. The drying process also helps turn the material into a compact and solid wall.

Benefits of Rammed Earth Construction

Building with rammed earth has the following benefits:

- Highly sustainable: Rammed earth is one of the most sustainable construction materials because it can be produced locally in the required volume without depleting natural resources, sometimes using exclusively on-site materials.

- High thermal mass: Rammed earth buildings have high thermal mass. Therefore, they absorb heat during the day and release it gradually at night. This helps to even out temperatures across the day and reduce energy use in heating and ventilation.

- Fire-resistant: Earth doesn’t burn, therefore, rammed earth structures don’t catch fire easily.

- Low maintenance: When built correctly, rammed earth structures require minimal maintenance and upkeep.

- Recyclable: Since rammed earth walls are made from natural materials, they are fully recyclable for other building projects.

Final Thoughts

Rammed earth is an ancient construction technique that has been used since the Neolithic era.

Some ancient structures, such as the Great Wall of China and Borough House Plantation, are still standing today, thanks to rammed earth’s durability.

Thus, rammed earth may be the answer if you’re looking for sustainable and low-maintenance construction materials.

If you enjoyed this article, you might also like our article “How Long Does Rammed Earth Last (Is It Durable)?” which looks at the factors that affect how long rammed earth walls last, whether they can be used for load-bearing duties, and much more.