Everything You Need to Know About Bamboo Building Joints

One of the most critical aspects of building with bamboo is using the right joints to ensure structural integrity and longevity.

There are different bamboo building joints, each with a unique joinery approach to ensure a stable structure.

Using an inappropriate bamboo building joint can lead to severe damage. Therefore, it’s essential to research and pick the right joints for your project – getting this part right is critical to the structural integrity of your building.

In the rest of this article, I’ll discuss the different types of traditional and modern bamboo joints.

I’ll also discuss the tools you need for each bamboo building joint to help you construct a structurally sound building. Let’s get started!

The Uniqueness of Bamboo Building Joints

Why do you think bamboo building joints are unique compared to other materials like wood?

Bamboo joints are unique and complicated because bamboo is tapered and hollow. Furthermore, besides not being perfectly circular, bamboo has nodes at varying distances along the culms.

The above features complicate the process of making bamboo building joints in the following ways:

- Hollowness: Bamboo’s hollow nature means you can’t use conventional materials like wood nails. Instead of joining the bamboo, these nails will split it.

- Tapered nature: Tapering means bamboo culms have varying diameters along their length – the top end is narrower than the bottom end. Bamboo’s tapered nature makes joining hard since you’ll have to create holes with different diameters based on the culm size at a specific point. Narrower ends will need narrower holes.

- Imperfect shape: Bamboo culms are not perfectly round, so you need the expertise to use joinery techniques like dowels or pegs without splitting the stem.

- Presence of nodes: Nodes are the joints in bamboo that mark the beginning and end of culm segments. These nodes create irregularities in the culm’s shape because they are typically thicker and harder than the internodes. Moreover, the nodes have varying diameters compared to the internodes. This makes it hard to achieve a smooth, seamless joint.

Now that you know why it can be challenging to create bamboo joints, let’s move to bamboo joinery techniques.

How Is Bamboo Joined Together?

There are two basic ways of joining bamboo together:

- Traditional or vernacular methods

- Modern bamboo joinery methods

Let’s discuss each of these bamboo joinery methods below.

Traditional or Vernacular Bamboo Joints

These are the bamboo joinery methods used in ancient times before bamboo got widely adopted in modern architecture.

Although cheaper, most of these techniques suffer from weaknesses or deformation, which can weaken the bamboo.

The following are traditional bamboo joinery methods.

Mortise-Tenon Joints

This is one of the oldest joinery methods, used at least 7,000 years ago.

Mortise-tenon bamboo joinery involves creating a tongue (tenon) in one piece of bamboo and a mortise in a mating bamboo.

The tongue inserts into the mortise in the mating piece. The tenon must fit snugly into the mortise for an excellent bamboo building joint.

Besides construction, mortise-tenon bamboo joinery is used in furniture making, especially in chairs, tables, and other items that require strong joints.

The mortise-tenon joint is common in bamboo construction because it doesn’t involve using nails or screws that can split the bamboo.

The process of joining bamboo through mortise-tenon joinery starts by cutting bamboo poles to the desired length and shape. Then, a mortise is cut into one piece of bamboo using a saw or chisel. The tenon is then cut into the end of a mating bamboo to fit snugly into the mortise.

Although mortise-tenon joints have the characteristic of minimal material consumption, they are best for non-hollow materials like wood.

This method punches a hole in the bamboo column or beam. Since bamboo is hollow, creating more holes compromises its strength. Consequently, the reliability of these joints in bamboo is not guaranteed.

Due to the drilling impact, bamboo mortise-tenon joints are coupled with lashings to enhance their stability.

Lashing Joints

This is a popular traditional bamboo joinery technique for a good reason; it’s cheap and can be adjusted easily.

In the ancient era, traditional natural materials like rattan, palm, hemp, and bamboo strips were the common lashing materials used for bamboo building joints. Nowadays, it’s common to see iron wire and plastic ties used for the same purpose.

Unlike the mortise-tenon joinery technique, lashing doesn’t involve drilling a hole into the bamboo culms. Therefore, this method upholds bamboo’s structural integrity. You can rest assured that the bamboo poles will remain firm and durable for whatever purpose the structure serves.

Now that you know this approach involves tying, you might be wondering how do you tie bamboo joints. Here is the procedure:

- Select suitable bamboo poles of the same diameter and length.

- Position the rods and hold them together in the desired configuration using a jig or clamps.

- Weave the natural fiber or rope around the joint in a specific pattern to secure the poles together. You can use a series of loops, knots, or twists to tie the lashes tightly around the bamboo poles.

- Pull the lash tightly and tie it off to create a strong, secure joint.

As I mentioned earlier, all traditional bamboo joining methods have shortcomings that contribute to the deformation of bamboo poles over time.

For lashing joints, joint stiffness is not guaranteed because of the high flexibility of the lashings. Consequently, any variation in the internal forces can break the lashings.

Moreover, lashings are susceptible to rain, sun, humidity, and temperature changes. When such environmental changes occur, the ropes become loose, corroded, or broken.

Luckily, you can enhance the ropes’ performance by treating them with oil immersion before lashing your bamboo poles.

You can also improve the joint’s strength by using more lashing material – the more times lashings wrap around the poles, the stronger the joint.

It’s worth mentioning that although lashing is among the traditional bamboo joinery methods, the approach is also common in modern bamboo architecture. For instance, in 2010, Vo Trong Nghia, a Vietnamese architect, built the Vietnam Pavilion using the bamboo lashing method.

Modern Bamboo Joinery Techniques

Modern bamboo joinery methods are meant to solve the challenges encountered in traditional methods. Specifically, these methods ensure durable bamboo building joints that don’t slip off.

The central concept behind modern bamboo joinery is that they use metal connectors to absorb much of the force applied to the joint by the building. This is unlike traditional joints that transmit the force directly to the raw bamboo components.

Modern bamboo joints include:

Bolted Joints

As the name suggests, this method joins bamboo poles using bolts. It’s the most common modern bamboo joinery method due to its:

- Excellent economic performance.

- High construction efficiency.

- Simple and reliable transmission force.

The basic idea behind bolted bamboo joints is to drill holes that match the bolt’s diameter on the bamboo rod. Then, insert a matching bolt through the hole and tighten it with nuts for a secure joint. All bolted bamboo joints are optimized based on this idea.

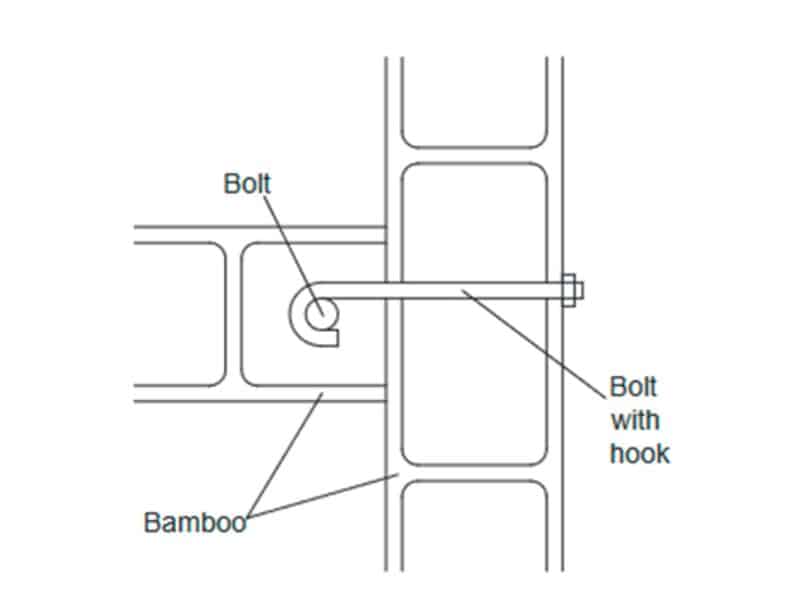

Besides using a single bolt and a pair of nuts, it’s possible to use two bolts to join two bamboo poles. For this approach, you need one of the bolts to have a hook at the end to connect the two bolts. A J bolt works well for this role. Here is an image showing an example of this type of bolted joint:

Fig 1: Bolted bamboo building joint. Source: Semantic Scholar

Before making bolted bamboo joints, a crucial point to note is that bamboos are prone to cracking during the bolting process. This is because their culms are thin-walled and can’t withstand the shear force due to drilling and bolting processes.

However, you can reduce the chances of your bamboo cracking or splitting when bolting by increasing the end distance of the bolt on the bamboo rod. The longer the end distance, the higher the bamboo’s resistance, and vice versa.

Steel Member and Steel Plate Joints

This advanced joinery approach uses steel components to connect bamboo poles. The steel components used include:

- Bolts

- Nuts

- Rebar hooks

- Hose clamps

- Steel pipes

This joinery method uses these steel components to ensure a sturdy joint that’s easy to assemble and disassemble.

Steel member and steel plate joining is also a versatile option that makes it possible to create multiple joints.

A T-shaped steel pipe is an excellent example of steel member and steel plate joints. Bamboo rods are inserted on either side of the T-shaped tube and fastened with bolts to achieve the desired joint.

Fig 2: T-shaped steel pipe. Source: Dreams Time

The only challenge you may encounter when using a T-shaped steel pipe to join bamboo rods is a mismatch between the size of the prefabricated steel pipe and the bamboo’s diameter. If this is the case, you’ll have to strip the bamboo to be the same size as the inner diameter of the pipe.

However, although stripping the bamboo rod ensures a snug fit for a secure joint, the process weakens the bamboo.

Besides the T-shaped steel pipe, you can use a prefabricated steel member to connect multiple bamboo culms. However, the shortcoming of this method is that joining many bamboo culms at a single point increases the main load.

Heavy loads make the bamboo walls weaker and less durable.

The best way to prevent heavy loads is by using a multi-layer metal cage design to join many bamboos. This design uses metal cages to secure the rods without drilling.

Frequently Asked Questions

What glue is used for bamboo?

Epoxy or yellow glue is suitable for gluing bamboo sections. Since bamboo is a type of grass, it’s made largely of cellulose. Therefore, any glue that works well on wood is also ideal for bamboo.

Is the stem of a bamboo jointed?

The stem of a bamboo is jointed through a series of internodes connected by nodes. The nodes make points where leaves and branches emerge from the stem.

How do you connect two bamboo sticks together?

You can connect two bamboo sticks by inserting the smaller stick into the larger one. You should lash the end of the larger stick to make the joint stronger and prevent splitting.

Final Thoughts

Although bamboo is an eco-friendly and sustainable building material, joining several bamboo rods to create the desired structure can be challenging. This is because bamboo is prone to splitting and deformation if not joined appropriately.

The best way to ensure successful bamboo building joints is by knowing the different types of bamboo joinery techniques and when to use them.

You should avoid conventional joinery tools like nails and screws because they can split your bamboo rods.

Bamboo plywood complements a bamboo structure beautifully, but where can you buy bamboo plywood for your next project? Here is a list of the 10 best bamboo plywood companies to buy from.